Last updated on

Pumping grease can be tricky due to the high viscosity and thickness of the material. There are different types of pumps in the market suitable for pumping grease, but some are more suitable than others.

In this blog, we are taking a look at the two most popular options: diaphragm pumps and peristaltic pumps. We discuss the advantages and disadvantages of each pump and which one is best for pumping grease.

What's Inside

Diaphragm Pumps: Versatile and robust

Diaphragm pumps, also known as membrane pumps, are a popular choice for pumping grease. Diaphragm pumps operate via a diaphragm movement that forms a temporary chamber into which fluids are sucked and then pushed forward.

They are used in various industries and are suitable for pumping corrosive chemicals, volatile solvents, viscous liquids, food products and pharmaceutical products, dirty water and abrasive suspensions, and more. Ancotech Lubrication Technology specializes in air-driven diaphragm pumps and offers a wide range of diaphragm pumps with a 1:1 pressure ratio.

They also provide free, no-obligation custom advice for any problem and carry out repairs and overhauls in their own workshop.

Peristaltic Pumps: The Best Choice for Pumping Grease

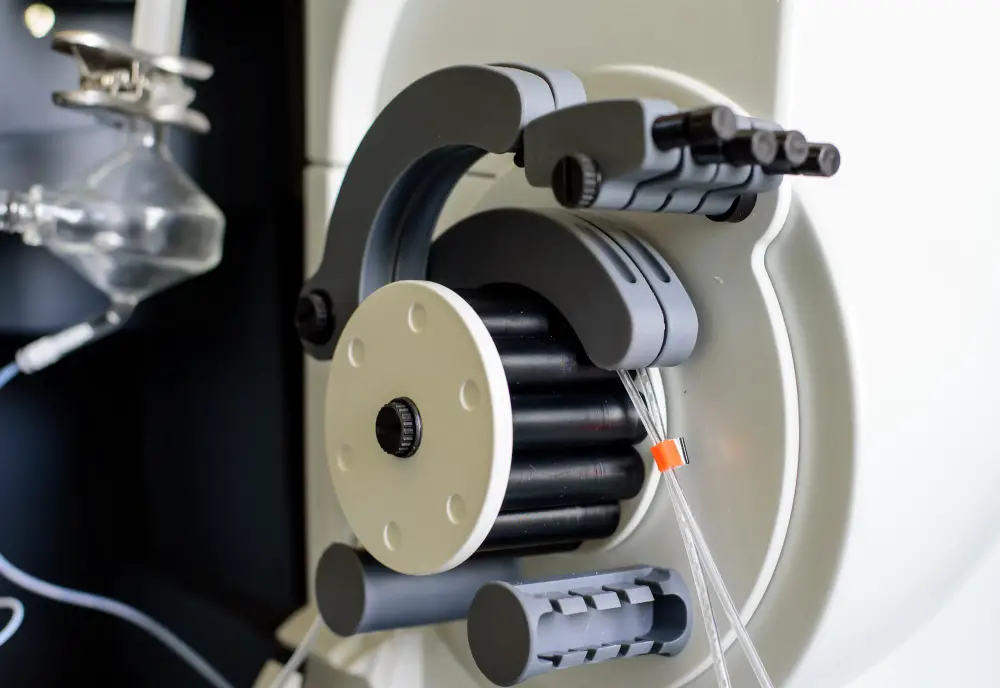

Peristaltic pumps are considered the best type of pump for pumping grease because of their gentle pumping action and ability to handle viscous fluids. In a peristaltic pump, the fluid is transported through a flexible hose that is compressed and released by a series of rollers, pushing the fluid in the desired direction.

There is a wide variety of tubing available for peristaltic pumps, allowing choices for different applications and material compatibility. It’s important to use the right lubricants specifically designed for peristaltic pumps to maintain their performance and extend the life of the hose when pumping grease.

Hoses in peristaltic pumps can experience fatigue between the rubber layers and the reinforcement layer, which can lead to hose defects.

Comparison of Diaphragm Pumps and Peristaltic Pumps

When choosing the right pump for pumping grease, it’s important to consider the specific characteristics and advantages of both diaphragm pumps and peristaltic pumps. Diaphragm pumps are versatile and robust, suitable for pumping a wide range of fluids, including grease, in various applications.

However, they may be less suitable for pumping very viscous fluids and may be more prone to wear when pumping abrasive materials. Peristaltic pumps are specifically designed for pumping viscous fluids like grease and offer a gentle pumping action that doesn’t damage the fluid. However, they may require more maintenance due to the wear and tear of the hoses.

Choose the Right Grease Pump for Your Application

Choosing the right grease pump is essential for successfully pumping grease. While both diaphragm pumps and peristaltic pumps are suitable for pumping grease, it’s important to consider their specific characteristics and advantages and choose based on the specific requirements of your application.

Peristaltic pumps are generally considered the best choice for pumping grease due to their gentle pumping action and ability to handle viscous fluids. To make the right choice, it is recommended to seek expert advice, like the expertise offered by Ancotech Lubrication Technology.

With their extensive range, fast delivery, and excellent customer service, they can help you find the ideal pump for your situation.