Last updated on

Because owning your dream kitchen might be pricier than you think, this article will delve into the reasons behind the high cost of kitchen cabinets and provide some wallet-friendly solutions.

Key takeaways:

- Wood cost: Different woods and eco-friendly sourcing drive up prices.

- Hardware cost: Quality hinges, slides, and decorative hardware increase expenses.

- Manufacturing: Custom-built cabinets and joinery add to the cost.

- Labor cost: Skilled craftsmanship and customization contribute to pricing.

- Shipping and delivery costs: Bulky cabinets involve higher transportation expenses.

What's Inside

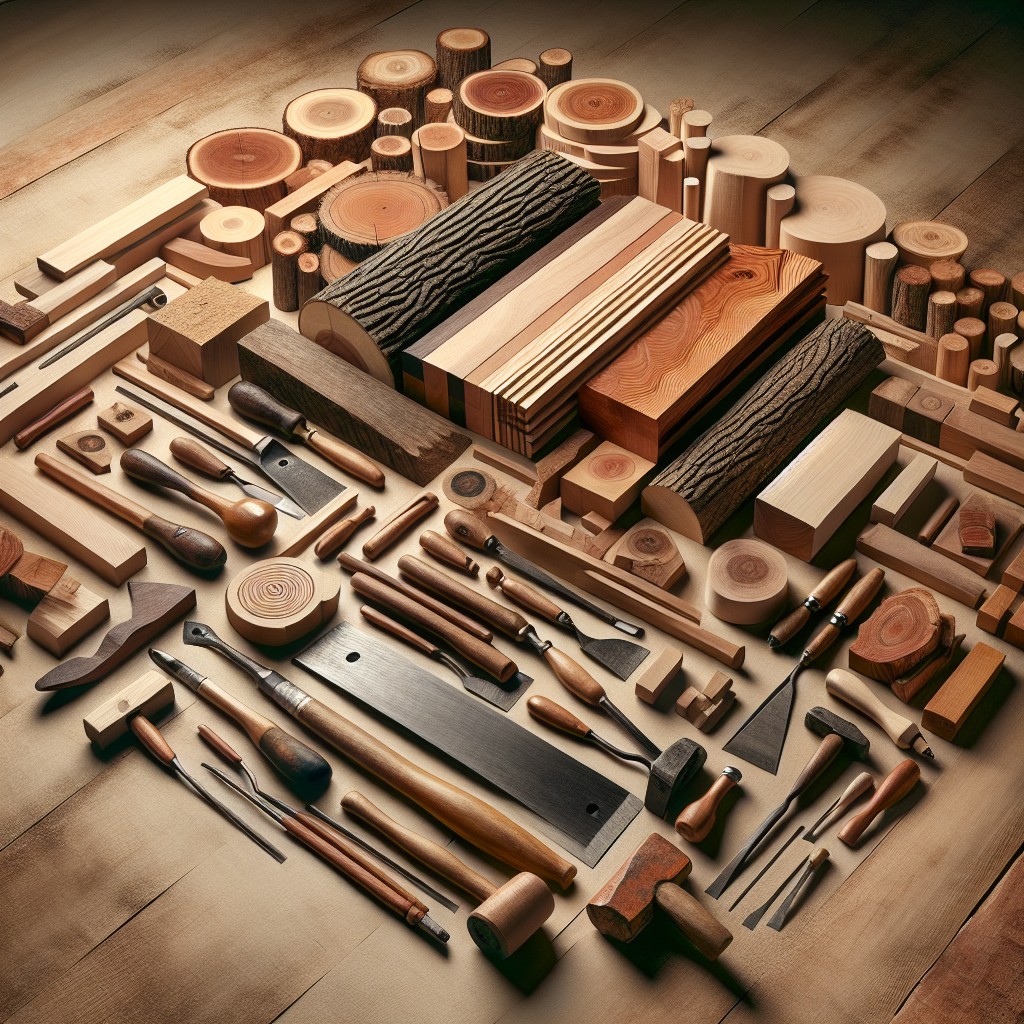

Wood Cost

Quality wood is fundamental in crafting durable and aesthetically pleasing cabinets, contributing significantly to overall cost. Different woods come with varying price tags; hardwoods such as maple and cherry are preferred for their fine grain and sturdiness but are more expensive than softer woods like pine. Additionally, the demand for eco-friendly and sustainably sourced wood further drives up prices. Market volatility can also affect the cost of lumber, and global events such as tariffs or trade disputes might impact the expense. Seeking out alternative or local wood sources could potentially mitigate these costs.

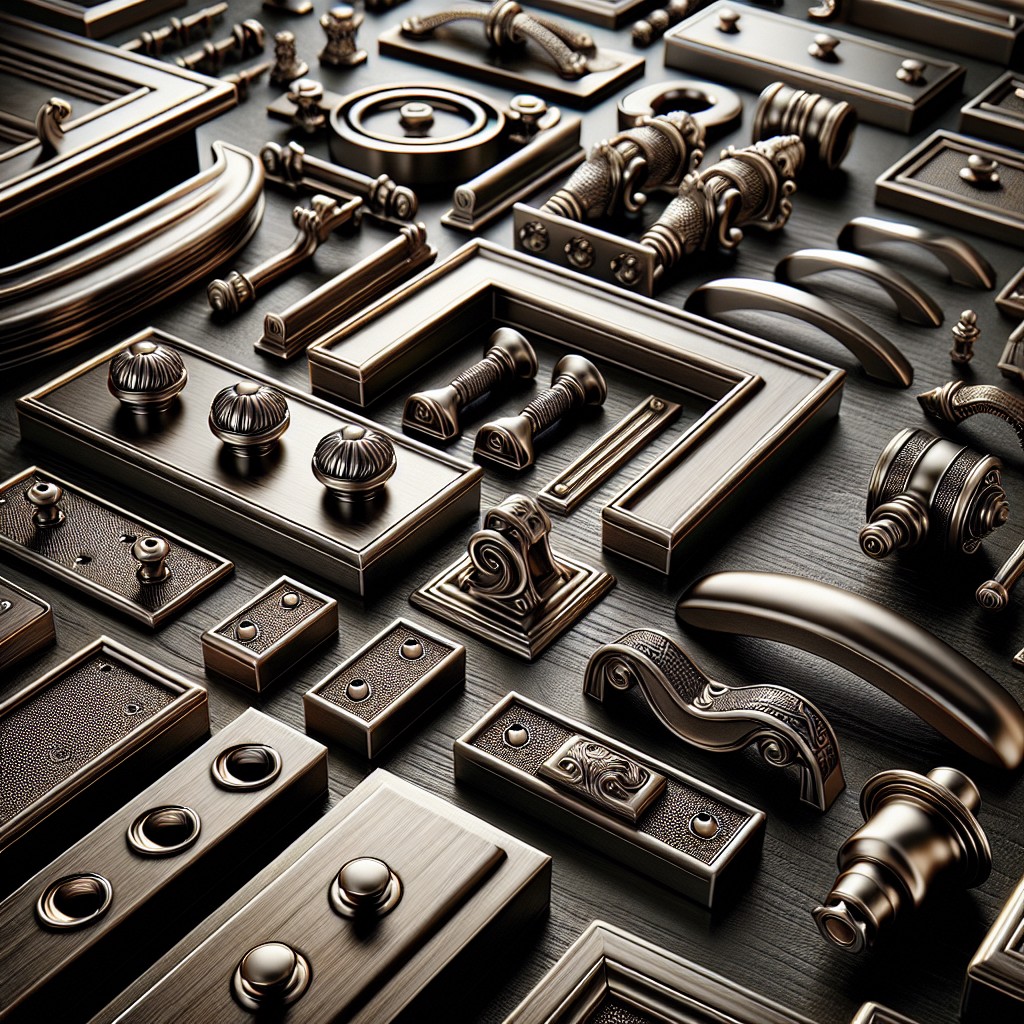

Hardware Cost

High-quality hinges and drawer slides matter to the functionality and longevity of cabinetry. These elements ensure that doors hang straight, drawers open smoothly, and both close correctly. Soft-close features, which prevent slamming and reduce wear, add to the cost but offer a luxurious feel frequently sought after in modern kitchens.

Additionally, knobs, pulls, and handles come in a variety of styles and finishes, allowing for personalization of your space. Opting for designer or custom hardware can significantly increase expenses. However, considering these pieces as the “jewelry” of your kitchen, they play a crucial role in the overall aesthetic.

Furthermore, the inclusion of built-in organizers or pull-out shelves requires additional hardware, which will add to the total cost, but contribute enormously to the functionality and efficiency of your kitchen workspace.

Manufacturing

High-quality kitchen cabinets are often custom-built to fit specific dimensions and preferences, involving precision and attention to detail. This manufacturing process, unlike mass production, is time-consuming and requires skilled craftsmen. Each cabinet must pass through multiple stages: cutting, assembling, sanding, and finishing, which adds to the cost.

The intricacies of joinery, where different parts are conjoined to ensure durability and aesthetic appeal, also play a pivotal role in manufacturing costs. Dovetail joints, for instance, are more elaborate but offer strength and longevity, factors that justify the higher price tag.

Advancements in technology have introduced computer-controlled machinery into the production line, improving accuracy and consistency but also leading to significant upfront investments in equipment. These costs, in turn, are factored into the final price of the cabinets.

Additionally, a portion of manufacturing expenses comes from quality control. Rigorous inspections at every stage ensure the final product meets strict standards, reducing the chances of defects but also elevating overall production costs.

Labor Cost

Craftsmanship requires skill and time, and cabinet makers often undergo extensive training to master their trade. Precision in cutting, assembling, and finishing each component translates to hours of meticulous labor, which all contribute to the cost.

The benefits of custom cabinets cannot be underestimated – tailored to fit your space perfectly, they enhance functionality and aesthetic appeal. However, the personal attention to detail comes at a premium.

Even semi-custom options involve labor, as modifications to standard sizes still require additional work. Automation has streamlined some processes but the installation remains largely a hands-on job, further impacting the final price tag. Remember, the expertise of professionals ensures that your cabinets will be durable and well-crafted, aspects that are often well worth the investment.

Shipping and Delivery Costs

Addressing the shipping and delivery aspect, cabinets are bulky and heavy, which inherently drives up transportation costs. Freight charges are calculated based on weight and size, so the more substantial the shipment, the higher the expense. Moreover, cabinets must be handled with care to avoid damage, necessitating additional packaging materials and possibly specialized freight services.

To mitigate these costs, consider the proximity of the manufacturer to the delivery site and explore potential discounts for bulk orders. Local sourcing can also reduce the impact of these charges on the overall cost of your kitchen cabinets.

Rethink Your Materials

When considering kitchen cabinets, solid hardwoods are often the go-to for their durability and timeless appeal. However, they come with a premium price tag. If you’re looking to keep costs down without sacrificing aesthetics, there are several material alternatives worth exploring:

- Thermofoil and Laminate: These are made from a plastic material that is heat-sealed to a particleboard or MDF core. They’re remarkably resistant to stains and easy to clean, which make them a practical, budget-friendly choice. While they can mimic the look of wood, be aware that they may not hold up as well over time.

- Bamboo: An eco-friendly and rapidly renewable resource, bamboo delivers both a contemporary look and the sturdiness similar to traditional wood. It’s less expensive than most hardwoods but offers comparable durability.

- Plywood: Although more expensive than particleboard, plywood still costs less than solid wood. It provides excellent strength for its weight and holds screws well, making for a solid cabinet construction. It can also be finished to look like more expensive wood.

- Particleboard and MDF: Engineered woods like particleboard and MDF (Medium Density Fiberboard) are significantly less costly than natural woods and can be covered with a wood veneer or a high-quality laminate to achieve the desired look.

Exploring these materials can lead to a significant reduction in your overall expenditure on kitchen cabinets without a substantial sacrifice on the overall look and functionality. Remember to weigh not just cost, but also the longevity and maintenance of your selected materials, to make the best choice for your kitchen.

Selecting a Mid-Range Brand

Focusing on mid-range brands can be a smart move for balancing budget with quality. These brands often provide the best of both worlds: durability and aesthetic appeal without the hefty price tag of luxury brands. They tend to offer a wide variety of styles and finishes that can suit various preferences.

When you opt for a mid-range brand, consider their warranty offers as a reflection of the confidence they have in their products. Look for brands with a solid reputation for customer service, in case issues arise. Moreover, read reviews and look for feedback on the cabinetry’s performance over time.

Additionally, mid-range manufacturers typically streamline their production methods, optimizing costs without compromising significantly on craftsmanship. They may offer standard sizes and finishes that reduce the price compared to fully customized solutions. Lastly, keep in mind that many mid-range options now feature some of the innovative designs and quality materials found in higher-end models, providing a luxurious feel without the extravagant price.

Design Complexity

Cabinets with intricate designs or custom features contribute significantly to the overall cost. If you opt for decorative moldings, glass inserts, or detailed paneling, these aesthetic touches demand additional time and precision during production. More complex designs often require skilled craftsmanship, which translates into a higher price tag. Additionally, specialized or unique joinery that enhances durability, like dovetail joints, can also add to the expense.

It’s a delicate balance – the more personalized and tailored the look, the greater the impact on your wallet. To manage costs without sacrificing style, consider simpler designs that maintain functionality but require less labor-intensive workmanship.

Material Alternatives

Exploring different materials can significantly impact the cost of your kitchen cabinets. If solid wood strains your budget, consider thermofoil or laminate, which mimic the look of wood at a fraction of the price. These synthetic options are not only cost-effective but also come with the added benefits of being easier to clean and more resistant to chipping and staining.

Additionally, medium-density fiberboard (MDF), while less expensive than natural wood, offers a smooth surface ideal for painting, allowing for a custom look without the custom price tag. Lastly, bamboo and particleboard present eco-friendly and budget-friendly alternatives, respectively, widening your choices for achieving both an aesthetic appeal and functional durability in your kitchen updates.

Market Dynamics

Market trends and economic factors play pivotal roles in the pricing of kitchen cabinets. Supply and demand exert significant influence; when demand for new kitchens is high, manufacturers may increase prices. Conversely, during a downturn, you might find prices more negotiable.

The cost of raw materials on international markets also impacts pricing. Tariffs and trade agreements can either lower import costs or drive them up, affecting how much consumers ultimately pay. Additionally, as environmental regulations become stricter, the processes to ensure sustainable sourcing and manufacturing can lead to higher costs.

It’s vital to keep an eye on these market dynamics as they can provide opportunities for savings when timed correctly.

FAQ

Is it cheaper to buy cabinets or have them built?

While the final cost can vary depending on material selection and labor cost, generally, buying pre-made cabinets tends to be more economical than having them custom-built.

What is the most expensive part of a kitchen remodel?

In a kitchen remodel, the cabinets represent the most costly element, often accounting for up to 29% of the total project budget.

Are high-end kitchen cabinets worth it?

High-end kitchen cabinets are worth the investment because they enhance the overall appeal of your home, and improve the aesthetic and ambiance of your kitchen area with their custom designs.

Is it worth it to get custom kitchen cabinets?

Yes, the investment in custom kitchen cabinets is certainly worthwhile given the unparalleled control over every detail, including size, height, style, hardware, and finish type and color.

How does the material influence the cost of kitchen cabinets?

The material greatly influences the cost of kitchen cabinets because high-quality, durable materials like hardwoods are usually more expensive than materials like particle board and laminate.

What factors contribute to the cost difference between stock, semi-custom, and custom kitchen cabinets?

The price disparities among stock, semi-custom, and custom kitchen cabinets hinge on factors like material, craftsmanship quality, level of customization, and installation expenses.

How can a budget-friendly kitchen remodel be achieved without compromising on cabinet quality?

Achieving a budget-friendly kitchen remodel without compromising cabinet quality can be done by purchasing unfinished cabinets and doing the painting or staining yourself, keeping existing cabinets and just replacing the doors, or buying at wholesale or auction prices.