Last updated on

Want to know what are carbon brushes used for and how useful are they in your household? Here’s the detailed answer.

Maintaining and understanding the functionality of industry equipment, household appliances, and automotive machines can help you surmount distress in cases of breakdown. Such knowledge is also valuable when making replacements in the occurrence of failures.

Carbon brushes are an essential part of the motor, generator, and DC machines that run on rotating parts and need electric power transmission from mechanical energy to power their moving parts. The brushes transmit electric current from static parts to rotating parts for the machine to function.

What's Inside

Understanding Carbon Brushes

Carbon brushes, such as Evolution carbon brushes, are conductive components that function as sliding contacts to transmit electrical currents from a source of mechanical energy at a static part to rotating parts in generators and motors. They protect the emission of sparks that can cause short-circuiting and are especially important in direct current (DC) machines.

Composition Of Carbon Brushes

A carbon brush is a composition of either one or more blocks of carbon. The number of blocks depends on the end-use of the carbon. It also contains one or more terminals, depending on the power transmission needs from the static parts to the rotating parts of the generator or the motors.

Depending on wear and tear from your usage and standard maintenance practices, replacing a carbon brush might occur occasionally.

Common Types Of Carbon Brushes

The four main types of carbon brushes include metal-graphites, graphites, electrographic, and carbon-graphites.

- Metal Graphite Brushes: Metal graphite brushes are a blend of fine metal powder and natural graphite. The brushes have low resistivity, hence their broad application, including places where the use of other brushes is ineffective.

- Graphite Brushes: Artificial or natural graphite is the main composition of graphite brushes, with a soft touch of resin. With controlled filming, the brushes have excellent riding abilities, making them ideal for slip rings and commutators.

They work well in areas with low density. Their protective ability safeguards commutators from harsh environments.

- Electrographic Brushes: Electrographic brushes are the most common in heavy-equipment industrial use, in mining sites, and the transportation industry. Their production occurs at high temperatures.

The brushes undergo a treatment that makes them stronger and improves their lubrication functionality, enhancing their longevity and suitability to environments with low humidity and extreme temperatures.

- Carbon-Graphite Brushes: Carbon-graphite brushes are the pioneers of brushes used in electrical current transmission. They work well under low-density environments, commonly among slower and older machine motors. The brushes run in high friction, reducing their suitability in modern motors.

Using Carbon Brushes

By default, domestic machines, industrial equipment, and automotive machines have an initial installation of carbon brushes. To maintain the efficiency of your home appliances, car, or equipment that you use for industrial purposes, replace a carbon brush when the machine parts wear out or during scheduled maintenance.

Here’s the common usage of carbon brushes:

Domestic Functions

Home machines demand less power than those in the industrial sector. Household appliances perform simple functions in the house from cleaning to trimming grass in the backyard. Also, a piece of equipment that has carbon brushes used at your home includes desktop printers and lawnmowers.

To avoid water wastage in your home, carbon brushes are also used in common appliances, such as dishwashers and laundry.

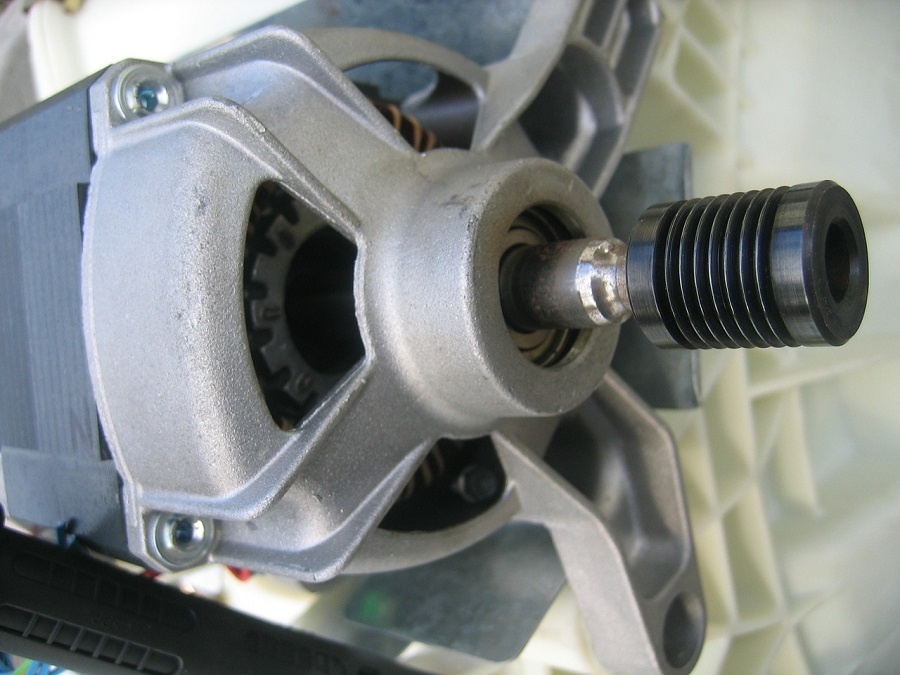

Industrial Functions

Industrial equipment with moving parts, like motors and generators, is prone to damage due to wear and tear from friction caused during movement. Carbon brushes slide between the moving parts and the static parts, absorbing the wear and tear effect and protect the motors from damage.

Some electrical motors and generators have commutators – rotary electrical switches to reverse current flow between external circuits and rotors. Carbon brushes form the point of contact between the static parts and the moving parts of the rotors, completing the circuit by allowing the flow of electrical current back and forth.

The core power conversion needs include DC generators, DC motors, universal motors, and all other direct currents (DC) equipment with rotors.

Automotive Industry Functions

Carbon brushes are also used in automotive power machines because they run on direct current (DC). Carbon brushes are also responsible for the car’s ability to steer and make the airbags operational when a car encounters an impact.

Mechanical energy transmits to moving parts usually alternators through carbon crushes in the form of alternating current after its conversion from direct current. To supply the energy needed for various parts of an automotive machine to function, the alternating current powers the alternators that necessitate the generation of magnetic fields. Carbon in the automotive industry is commonly used in cars that operate on oil or diesel.

Efficient machines that need an electric current to move their motors rely on carbon brushes. The brushes transmit power from a static source to the moving parts of motors and generators.

Carbon brushes fall into four main categories: electrographic brushes, metal graphite brushes, graphite brushes, and carbon-graphite brushes. Usages of carbon brushes can be domestic uses, automotive machines, and industrial equipment.